Epoxy resin

31 Products

-

12.20 € – 33.60 €The usual UV resin formula has been significantly improved by changing the hardening rate and mechanical properties (hardness) of the final product. UV Creation is made of acrylic and non-toxic materials. The product is in a convenient, easy and instantly usable package. Hardens instantly in 60 seconds with the help of a 36 W UV lamp or sunlight. Here you will find a suitable UV lamp Excellent quality: transparent UV epoxy reed, self-leveling, Cross-siding with UV rays, with a transparent and glossy surface, anti-scratching and anti-yellowing. UV resin is widely used to fill and manufacture decorative jewellery, clothing attachments, formal items, resin models, etc.

12.20 € – 33.60 €The usual UV resin formula has been significantly improved by changing the hardening rate and mechanical properties (hardness) of the final product. UV Creation is made of acrylic and non-toxic materials. The product is in a convenient, easy and instantly usable package. Hardens instantly in 60 seconds with the help of a 36 W UV lamp or sunlight. Here you will find a suitable UV lamp Excellent quality: transparent UV epoxy reed, self-leveling, Cross-siding with UV rays, with a transparent and glossy surface, anti-scratching and anti-yellowing. UV resin is widely used to fill and manufacture decorative jewellery, clothing attachments, formal items, resin models, etc. -

44.90 € – 177.00 €Transparent safe resin to cover your dishes and cutting boards! Completely non-toxic and certified for contact with food (even liquids). Suitable for creation, coating and model making! Ideal for creating trays, cutting boards, plates, glasses, cutlery, knife and tabletop, making souvenirs, creating a protective layer on printed images (photos, canvases, paintings), creating designer furniture, creating decorative and design elements, using input methods the number of items inside the resin. Only raw materials included in the list of substances authorised for contact with food have been used in the preparation process (Regulation No 220 of 26 April 1993).

44.90 € – 177.00 €Transparent safe resin to cover your dishes and cutting boards! Completely non-toxic and certified for contact with food (even liquids). Suitable for creation, coating and model making! Ideal for creating trays, cutting boards, plates, glasses, cutlery, knife and tabletop, making souvenirs, creating a protective layer on printed images (photos, canvases, paintings), creating designer furniture, creating decorative and design elements, using input methods the number of items inside the resin. Only raw materials included in the list of substances authorised for contact with food have been used in the preparation process (Regulation No 220 of 26 April 1993). -

23.40 € – 40.70 €Epoxy reiik with very good transparency. Binary epoxy resin, designed primarily for jewellery, forms and creative activities. Due to its specific composition and long catalysis durability, Liquidissima is very well suited for coating with a layer up to 1 cm thick. But is also suitable for thin coverings (1mm) and smaller quantities for layers 2cm thick. A product for making art, which has even better characteristics in terms of transparency, low viscosity (reduces the formation of bubbles) and self-leveling properties compared to "Transparent". Thanks to these qualities, the creation has an even more crystalline appearance. The product is also suitable for all colors and toners designed for epoxy, but it is necessary to make sure that the percentage of the pigment is between 0.1% and 2%.

23.40 € – 40.70 €Epoxy reiik with very good transparency. Binary epoxy resin, designed primarily for jewellery, forms and creative activities. Due to its specific composition and long catalysis durability, Liquidissima is very well suited for coating with a layer up to 1 cm thick. But is also suitable for thin coverings (1mm) and smaller quantities for layers 2cm thick. A product for making art, which has even better characteristics in terms of transparency, low viscosity (reduces the formation of bubbles) and self-leveling properties compared to "Transparent". Thanks to these qualities, the creation has an even more crystalline appearance. The product is also suitable for all colors and toners designed for epoxy, but it is necessary to make sure that the percentage of the pigment is between 0.1% and 2%. -

44.90 € – 530.40 €Very high viscosity transparent epoxy resin for professional use. Suitable for creating paintings and art covers in the style of "Ocean Art". Attention: Service life (150 g at 30 ° C): 40 minutes, Perfectly smooth and moisture-resistant surface. The ideal Art Pro is ideal as a coating material, leaving a smooth and moisture-resistant surface. Suitable for covering paintings and other surfaces (even floors). Layer thickness from 1 mm to 5 mm. ArtPro black is free of solvents and odor.

44.90 € – 530.40 €Very high viscosity transparent epoxy resin for professional use. Suitable for creating paintings and art covers in the style of "Ocean Art". Attention: Service life (150 g at 30 ° C): 40 minutes, Perfectly smooth and moisture-resistant surface. The ideal Art Pro is ideal as a coating material, leaving a smooth and moisture-resistant surface. Suitable for covering paintings and other surfaces (even floors). Layer thickness from 1 mm to 5 mm. ArtPro black is free of solvents and odor. -

41.70 € – 550.70 €A transparent self-leveling epoxy system that is resistant in its properties to UV radiation and provides a strong and shiny protective layer. Artists' epoxy reik ART PRO is specially developed for "pour painting" (casting technique). Due to its dense structure, it does not spill off the work surface, but slowly extends to the corners of the canvas. ART PRO allows you to maintain its original design without changing the design when poured over with transparent resin. Thanks to a special formula, paint layers do not expand or mix (unless you voluntarily intervene). The finish is perfectly smooth and resistant to moisture. Art Pro is perfect for covering wall decorations, paintings and surfaces (as well as for floors). Art Pro can be used from 1mm to 5mm layer pain. If you need to pour molds or jewelry, we recommend Resinpro TRANSPARENTE resin.

41.70 € – 550.70 €A transparent self-leveling epoxy system that is resistant in its properties to UV radiation and provides a strong and shiny protective layer. Artists' epoxy reik ART PRO is specially developed for "pour painting" (casting technique). Due to its dense structure, it does not spill off the work surface, but slowly extends to the corners of the canvas. ART PRO allows you to maintain its original design without changing the design when poured over with transparent resin. Thanks to a special formula, paint layers do not expand or mix (unless you voluntarily intervene). The finish is perfectly smooth and resistant to moisture. Art Pro is perfect for covering wall decorations, paintings and surfaces (as well as for floors). Art Pro can be used from 1mm to 5mm layer pain. If you need to pour molds or jewelry, we recommend Resinpro TRANSPARENTE resin. -

17.20 € – 38.70 €Epoxy reike with fast drying time and good transparency, ideal for pouring into silicone molds. Professional product specially designed for jewellery processing and artistic creation. The epoxy recycle developed gives better transparency, strength and shine, but much shorter hardening time as traditional resins. The cast of the mold can be extracted from the silicone mold take after 6 hours, but achieves maximum strength (not deformed) after 24-48 hours.

17.20 € – 38.70 €Epoxy reike with fast drying time and good transparency, ideal for pouring into silicone molds. Professional product specially designed for jewellery processing and artistic creation. The epoxy recycle developed gives better transparency, strength and shine, but much shorter hardening time as traditional resins. The cast of the mold can be extracted from the silicone mold take after 6 hours, but achieves maximum strength (not deformed) after 24-48 hours. -

- 35 % Discount

23.93 € – 57.93 €High-performance transparent resin is a two-piece product designed as a protective layer on top to protect against heat and scratches. The composition of "HEAT PRO" ensures the highest quality long-lasting smooth, glossy, scratch and heat-resistant finish. Ideal for both DIY/home users and industrial consumers. The product can be easily applied and the surface can be reused within 24 hours. Transparent self-leveling UV-resistant epoxy resin that creates a protective layer against heat and scratches. The protective layer should be made 1-2.5 mm. It is very necessary to monitor the humidity in the room, the drier the air, the better the result will remain. In a room with very high humidity, it is not recommended to use the product. The product is slightly elastic after drying and is not sandable or polishable. The product is not suitable for use with pigments or additives. When it comes to the colored epoxy work you want to cover with Heat Pro. First cover the colored work with transparent and clean epoxy, and only then after 24-48 hours cover with heat-resistant Heat Pro product. It is advisable to make an intermediate joint to increase the adhesion of different layers.

- 35 % Discount

23.93 € – 57.93 €High-performance transparent resin is a two-piece product designed as a protective layer on top to protect against heat and scratches. The composition of "HEAT PRO" ensures the highest quality long-lasting smooth, glossy, scratch and heat-resistant finish. Ideal for both DIY/home users and industrial consumers. The product can be easily applied and the surface can be reused within 24 hours. Transparent self-leveling UV-resistant epoxy resin that creates a protective layer against heat and scratches. The protective layer should be made 1-2.5 mm. It is very necessary to monitor the humidity in the room, the drier the air, the better the result will remain. In a room with very high humidity, it is not recommended to use the product. The product is slightly elastic after drying and is not sandable or polishable. The product is not suitable for use with pigments or additives. When it comes to the colored epoxy work you want to cover with Heat Pro. First cover the colored work with transparent and clean epoxy, and only then after 24-48 hours cover with heat-resistant Heat Pro product. It is advisable to make an intermediate joint to increase the adhesion of different layers. -

44.50 € – 1061.50 €EPOXYTABLE 10 is a non-toxic epoxy resin for the production of boards. Up to 10 cm thick layer can be achieved in one pour. The finished product is highly resistant to yellowing and scratching. Due to the superior exothermic reaction, thicker layers can be cast without overheating and deformation of the material. Perfectly transparent and UV resistant.

44.50 € – 1061.50 €EPOXYTABLE 10 is a non-toxic epoxy resin for the production of boards. Up to 10 cm thick layer can be achieved in one pour. The finished product is highly resistant to yellowing and scratching. Due to the superior exothermic reaction, thicker layers can be cast without overheating and deformation of the material. Perfectly transparent and UV resistant. -

Sold out

7.34 €Portable UV lamp. Lighting: 9 LEDs emit UV waves (ultraviolet light). Power consumption: 9W. Works with 3 batteries (not included). Long lasting: Compared to traditional bulbs, LEDs have a longer lifespan of 50,000 hours, which ensures energy savings. Color: black. Ideal for UV resin. Suitable for use with UV-Creation

Sold out

7.34 €Portable UV lamp. Lighting: 9 LEDs emit UV waves (ultraviolet light). Power consumption: 9W. Works with 3 batteries (not included). Long lasting: Compared to traditional bulbs, LEDs have a longer lifespan of 50,000 hours, which ensures energy savings. Color: black. Ideal for UV resin. Suitable for use with UV-Creation -

- 29 % Discount

15.99 € – 146.50 €NATURESIN🍀is a binary water-based acrylic polymer/mineral resin system. 🌱 environmentally friendly 🌱 non-toxic 🌱 VOC-free 🌱 vegan 🌱 without solvents 🌱 mineral product NATURESIN🍀is a completely new product of ResinPro for your creation: easy to use, solvent-free and completely poison-free! The product is perfect for creating trays, cup trays, ashtrays, plates, jewelry boxes, flowerpots, cutting boards, candle holders, mobile phone holders and various household and office items! Naturesin🍀product is strong and durable. This makes this product ideal for the kind of creation that has to withstand the effects of the environment and is designed for outdoor use. It can be painted with many Resin Pro colors and pigments, and after hardening it can be painted in any color!!

- 29 % Discount

15.99 € – 146.50 €NATURESIN🍀is a binary water-based acrylic polymer/mineral resin system. 🌱 environmentally friendly 🌱 non-toxic 🌱 VOC-free 🌱 vegan 🌱 without solvents 🌱 mineral product NATURESIN🍀is a completely new product of ResinPro for your creation: easy to use, solvent-free and completely poison-free! The product is perfect for creating trays, cup trays, ashtrays, plates, jewelry boxes, flowerpots, cutting boards, candle holders, mobile phone holders and various household and office items! Naturesin🍀product is strong and durable. This makes this product ideal for the kind of creation that has to withstand the effects of the environment and is designed for outdoor use. It can be painted with many Resin Pro colors and pigments, and after hardening it can be painted in any color!! -

33.60 € – 134.60 €EPOXYWOOD epoxy resin for wood – protective coating, restoration, reinforcement. Epoxywood is designed to make a protective layer for wood, restoration and reinforcement. Epoxywood protects, strengthens and polishes wood, thanks to its low viscosity, the liquid is very well absorbed into the pores of the wood. The product can be used on all types of wood, but the product can also be used on fiberglass and metal. In addition to surface protection, epoxywood very well highlights the texture of wood and creates a very aesthetic appearance.

33.60 € – 134.60 €EPOXYWOOD epoxy resin for wood – protective coating, restoration, reinforcement. Epoxywood is designed to make a protective layer for wood, restoration and reinforcement. Epoxywood protects, strengthens and polishes wood, thanks to its low viscosity, the liquid is very well absorbed into the pores of the wood. The product can be used on all types of wood, but the product can also be used on fiberglass and metal. In addition to surface protection, epoxywood very well highlights the texture of wood and creates a very aesthetic appearance. -

33.60 € – 190.70 €Art Pro Green transparent BIO-sustainable resin An epoxy resin with a high BIO content that can be used for coating in the art sector: an innovative eco-sustainable product that provides all the performance of traditional epoxy resins. This particular resin was developed by the Resin Pro team to ensure maximum respect for the environment for its customers, without sacrificing the quality of the finished product. The low exothermic reaction allows up to 2 cm to be poured without the risk of yellowing or overheating, ensuring a perfectly transparent product (but in any case can be coloured as desired) and resistance to scratches. The result of a collaboration between organic engineering and epoxy resin, the blend is the result of years of long and innovative research, with at least 40% of biological elements. Choosing Art Pro Green by ResinPro® means the same quality as classic ResinPro products, but with less environmental impact. The chemical derived from biomass conversion significantly reduces the use of petrochemical sources.

33.60 € – 190.70 €Art Pro Green transparent BIO-sustainable resin An epoxy resin with a high BIO content that can be used for coating in the art sector: an innovative eco-sustainable product that provides all the performance of traditional epoxy resins. This particular resin was developed by the Resin Pro team to ensure maximum respect for the environment for its customers, without sacrificing the quality of the finished product. The low exothermic reaction allows up to 2 cm to be poured without the risk of yellowing or overheating, ensuring a perfectly transparent product (but in any case can be coloured as desired) and resistance to scratches. The result of a collaboration between organic engineering and epoxy resin, the blend is the result of years of long and innovative research, with at least 40% of biological elements. Choosing Art Pro Green by ResinPro® means the same quality as classic ResinPro products, but with less environmental impact. The chemical derived from biomass conversion significantly reduces the use of petrochemical sources. -

Sold out

15.30 € – 17.90 €BioEpoxy offers the same good quality as the classic ResinPro products, but with less environmental impact. The product, derived from biomass conversion, significantly reduces the use of petrochemical sources. BioEpoxy by ResinPro® is made up of 30% renewable materials, such as grain epoxidation processes, to minimise the impact on the environment and your health! ☘️ 【SAFE AND CERTIFIED】 Resin with a high percentage of BIO ingredients, certified USDA BioPreferred (USDA BioPreferredSM). This BIO epoxy is ideal for jewelry, art making, surface coating, modeling and DIY. 🔍 【IDEAD QUALITY】 Certified non-toxic, odourless, solvent-free, vegan, VOC-free, non-flammable and completely safe. ✔️ 【100% MADE IN ITALY】 Formula developed and produced in Italy specifically for the art world. Completely transparent, equipped with new anti-yellowing UV filters, liquid enough to avoid air bubbles. Very glossy and self-leveling. Since it is a two-component resin, simply mix VACUUM A + VACUUM B in the ratio indicated on the package and allow to set without any additional additives. Can be coloured as desired. Basic properties: Excellent transparency Stability to UV radiation Excellent mechanical resistance Long processing time Bio certified Odourless Solvent free Vegan VOC free Non flammable

Sold out

15.30 € – 17.90 €BioEpoxy offers the same good quality as the classic ResinPro products, but with less environmental impact. The product, derived from biomass conversion, significantly reduces the use of petrochemical sources. BioEpoxy by ResinPro® is made up of 30% renewable materials, such as grain epoxidation processes, to minimise the impact on the environment and your health! ☘️ 【SAFE AND CERTIFIED】 Resin with a high percentage of BIO ingredients, certified USDA BioPreferred (USDA BioPreferredSM). This BIO epoxy is ideal for jewelry, art making, surface coating, modeling and DIY. 🔍 【IDEAD QUALITY】 Certified non-toxic, odourless, solvent-free, vegan, VOC-free, non-flammable and completely safe. ✔️ 【100% MADE IN ITALY】 Formula developed and produced in Italy specifically for the art world. Completely transparent, equipped with new anti-yellowing UV filters, liquid enough to avoid air bubbles. Very glossy and self-leveling. Since it is a two-component resin, simply mix VACUUM A + VACUUM B in the ratio indicated on the package and allow to set without any additional additives. Can be coloured as desired. Basic properties: Excellent transparency Stability to UV radiation Excellent mechanical resistance Long processing time Bio certified Odourless Solvent free Vegan VOC free Non flammable -

-17% Discount

-17% Discount

22.43 €Original price was: 22.43 €.18.69 €Current price is: 18.69 €.One to one 500g The product is designed specifically for jewellery and creative projects. The use of the product is made easy by the resin-hardener ratio of 1:1, non-toxicity, transparency and durability. If desired, the One-to-One mixture can be poured into silicone molds, used as a protective layer in printed images (photos, canvases, paintings), used in the manufacture of special decorative and design elements with various filling agents. This binary epoxy resin is designed to be covered in a thin layer (from 1mm) and poured into forms up to 2cm thick. The product is completely transparent, self-leveling and ensures excellent coherence between different materials. Low viscosity of binary resin reduces the formation of air bubbles after drying out and facilitates the impregnation of carbon fibers. Excellent resistance to environmental humidity ensures a glossy and transparent surface. The product is suitable for use with most of the tinting colours for epo resin. -

25.50 €Very liquid polyurethane reed for casting and fast prototypes in the field of modeling and automation. Prototypes made with silicone molds and polyurethane resin can be used for pre-treatment, strength and dimensional tests to enhance the detail before mass production of the finished product. Our polyurethane reed allows you to produce even, shiny and durable models or artistic creations in 2 minutes. It can be painted with the colors of the series "Colorfun".

25.50 €Very liquid polyurethane reed for casting and fast prototypes in the field of modeling and automation. Prototypes made with silicone molds and polyurethane resin can be used for pre-treatment, strength and dimensional tests to enhance the detail before mass production of the finished product. Our polyurethane reed allows you to produce even, shiny and durable models or artistic creations in 2 minutes. It can be painted with the colors of the series "Colorfun". -

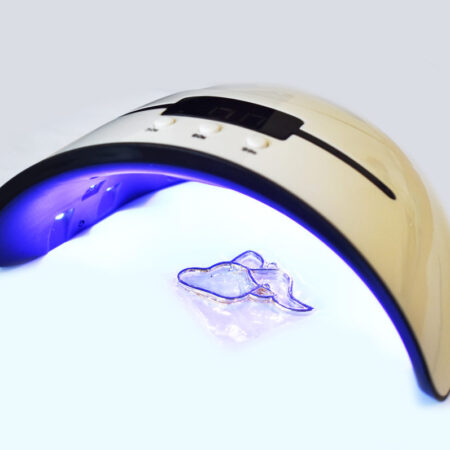

16.83 €Ideal UV lamp to harden the UV resin and speed up the hardening process. With the device it is possible to get a glossy and dry surface in a matter of seconds. Thanks to the internal refractive system, the lamp emits light FROM ALL DIRECTIONS, and the epoxy hardens in a short time. The purpose of the lamp is to harden UV resin / gel polish. The life of the lamp is equal to 50, 000 hours. Suitable for professionals as well as self-testers. A 36 Wt UV lamp reduces the UV/gel resin hardening time by 50% compared to conventional devices. Equipped with 12 Led bulbs. Automatic sensors and preset timers. The UV lamp is equipped with automatic sensors that allow the lamp to go into operation when putting the work under the lamp. Sensors automatically stop the activity of the device when you take your creation out from under the lamp. The lamp is suitable for gels compatible with LED and UV technology, including regenerating gels and nail art.

16.83 €Ideal UV lamp to harden the UV resin and speed up the hardening process. With the device it is possible to get a glossy and dry surface in a matter of seconds. Thanks to the internal refractive system, the lamp emits light FROM ALL DIRECTIONS, and the epoxy hardens in a short time. The purpose of the lamp is to harden UV resin / gel polish. The life of the lamp is equal to 50, 000 hours. Suitable for professionals as well as self-testers. A 36 Wt UV lamp reduces the UV/gel resin hardening time by 50% compared to conventional devices. Equipped with 12 Led bulbs. Automatic sensors and preset timers. The UV lamp is equipped with automatic sensors that allow the lamp to go into operation when putting the work under the lamp. Sensors automatically stop the activity of the device when you take your creation out from under the lamp. The lamp is suitable for gels compatible with LED and UV technology, including regenerating gels and nail art. -

Sold out

20.40 €CARBON AND GLASS FIBER EPOXY – Epoxy reed for carbon and glass fiber lamination The product is manufactured to guarantee maximum mechanical strength and good ease of use when impregnating materials. When applied to epoxy technical fabrics at room temperature, it guarantees maximum mechanical durability and thanks to good resistance to space wet, the final finish is glossy.

Sold out

20.40 €CARBON AND GLASS FIBER EPOXY – Epoxy reed for carbon and glass fiber lamination The product is manufactured to guarantee maximum mechanical strength and good ease of use when impregnating materials. When applied to epoxy technical fabrics at room temperature, it guarantees maximum mechanical durability and thanks to good resistance to space wet, the final finish is glossy. -

19.30 € – 48.20 €Binary white polyurethane resin with high fluidity and very good mechanical strength. Suitable for hobby creation and making prototypes in the modeling sector. Fast catalysis speed (30 minutes) is perfect for quickly and accurately recreating objects of all sizes. Liquid resin can be easily painted with any compatible color paste. Also, after hardening, the finished work with acrylic paints can be painted.

19.30 € – 48.20 €Binary white polyurethane resin with high fluidity and very good mechanical strength. Suitable for hobby creation and making prototypes in the modeling sector. Fast catalysis speed (30 minutes) is perfect for quickly and accurately recreating objects of all sizes. Liquid resin can be easily painted with any compatible color paste. Also, after hardening, the finished work with acrylic paints can be painted. -

22.30 €3D - FINISH "Fast" coating for 3D printed products The epoxy system with two components consists of 250 g resin (component A) and 120 g of hardener (component B). It is developed specifically for use in the 3D sector, it does not drip or cover small details, exactly following all forms of printing. Mixing ratio 100:45; For an area of 5 cm2 you only need 25 g Drying speed At temperatures from 20°C to 3 hours At temperatures from 30°C to solid for 2 hours

22.30 €3D - FINISH "Fast" coating for 3D printed products The epoxy system with two components consists of 250 g resin (component A) and 120 g of hardener (component B). It is developed specifically for use in the 3D sector, it does not drip or cover small details, exactly following all forms of printing. Mixing ratio 100:45; For an area of 5 cm2 you only need 25 g Drying speed At temperatures from 20°C to 3 hours At temperatures from 30°C to solid for 2 hours -

99.00 € – 445.00 €LUXRESIN – Revolutsiooniline polüuretaanvaik Innovatsiooniline ja vastupidav polüuretaanvaik teie kõige julgemate projektide jaoks! LUXRESIN on revolutsiooniline kahekomponentne polüuretaanvaik väga paksude valude jaoks. Selle täiustatud valem pakub kristallselget tulemust ja erakordset vastupidavust kollasusele, tagades veatu tulemuse nii sise- kui ka väliskeskkonnas isegi intensiivse päikese käes. LUXRESINi eripäraks on selle erakordne võime valada ilma piiranguteta suurtes paksustes. Seda tänu väga madalale eksotermilisusele reaktsioonile (<50°C) . Lisaks sellele on pärast vaigu kivistumist tootel kõrgetasemelised mehaanilised omadused, ületamatu pinna kõvadus ja kulumiskindlus. Ideaalne julgete ja uuenduslike projektide jaoks. LUXRESIN ideaalne valik neile, kes otsivad kvaliteetset toodet, mis ühendab endas esteetika, vastupidavuse ja mitmekülgsuse. 💎 Võrratu läbipaistvus: erakordne selgus, mis murrab ja peegeldab valgust hämmastaval viisil. 🛡️Täiustatud kollasusevastane toime: loodud vastu pidama kõige raskematele atmosfääritingimustele, säilitades selle ilu aja jooksul. 🔨Eriline mehaaniline vastupidavus: tööstusliku taseme pinna kõvadus ja kulumiskindlus pärast kõvenemist. 🎨Piiramatu hulk loomingulisi rakendusi: ideaalne väga paksude valandite jaoks ilma ülekuumenemisohuta (tipp <50°C). 🌱 Keskkonnasõbralik ja ohutu: teadlik valik keskkonnale, tegemata järeleandmisi kvaliteedis.

99.00 € – 445.00 €LUXRESIN – Revolutsiooniline polüuretaanvaik Innovatsiooniline ja vastupidav polüuretaanvaik teie kõige julgemate projektide jaoks! LUXRESIN on revolutsiooniline kahekomponentne polüuretaanvaik väga paksude valude jaoks. Selle täiustatud valem pakub kristallselget tulemust ja erakordset vastupidavust kollasusele, tagades veatu tulemuse nii sise- kui ka väliskeskkonnas isegi intensiivse päikese käes. LUXRESINi eripäraks on selle erakordne võime valada ilma piiranguteta suurtes paksustes. Seda tänu väga madalale eksotermilisusele reaktsioonile (<50°C) . Lisaks sellele on pärast vaigu kivistumist tootel kõrgetasemelised mehaanilised omadused, ületamatu pinna kõvadus ja kulumiskindlus. Ideaalne julgete ja uuenduslike projektide jaoks. LUXRESIN ideaalne valik neile, kes otsivad kvaliteetset toodet, mis ühendab endas esteetika, vastupidavuse ja mitmekülgsuse. 💎 Võrratu läbipaistvus: erakordne selgus, mis murrab ja peegeldab valgust hämmastaval viisil. 🛡️Täiustatud kollasusevastane toime: loodud vastu pidama kõige raskematele atmosfääritingimustele, säilitades selle ilu aja jooksul. 🔨Eriline mehaaniline vastupidavus: tööstusliku taseme pinna kõvadus ja kulumiskindlus pärast kõvenemist. 🎨Piiramatu hulk loomingulisi rakendusi: ideaalne väga paksude valandite jaoks ilma ülekuumenemisohuta (tipp <50°C). 🌱 Keskkonnasõbralik ja ohutu: teadlik valik keskkonnale, tegemata järeleandmisi kvaliteedis. -

157.10 € – 561.00 €EPOXY PREMIUM Designed for work up to 7,5cm thick. Epoxy Premium is the flagship of the ResinPro range, using the most advanced formulations with a single goal: perfect casts, bubble-free, deformation-free and long-lasting. Created specifically for wood and resin board applications. Also very suitable for large mouldings and artistic work. Very low exothermic reaction allows large thicknesses to be moulded WITHOUT OVERCASTING AND DEFORMATION. Perfectly VISUAL, with a delicate bluish tint. To create smaller objects, it is possible to increase the thickness of the casting up to 10cm, which must be controlled at 15°C and the volume of the epoxy mixture must not exceed 15kg per casting. Example: 100cmx10cm x 10cm epoxy lamp. The product has been combined in such a way that anyone can make a simple riverbed, or other artistic work as easily as possible. Epoxy Premium will give you a great result without effort, because: ➡ The product has a low exothermic reaction, for castings up to 7,5 cm thick! ➡ Anti-UV filters provide a 10 year guarantee without yellowing - special light blue tint ensures greater durability over time. ➡ High mechanical resistance surface ensures maximum scratch resistance! ➡ The product is easy to use, ideal for professionals and amateurs alike ➡ Low viscosity for excellent air bubble removal ➡ The product has a long working time to allow intervention and repair of aesthetic defects.

157.10 € – 561.00 €EPOXY PREMIUM Designed for work up to 7,5cm thick. Epoxy Premium is the flagship of the ResinPro range, using the most advanced formulations with a single goal: perfect casts, bubble-free, deformation-free and long-lasting. Created specifically for wood and resin board applications. Also very suitable for large mouldings and artistic work. Very low exothermic reaction allows large thicknesses to be moulded WITHOUT OVERCASTING AND DEFORMATION. Perfectly VISUAL, with a delicate bluish tint. To create smaller objects, it is possible to increase the thickness of the casting up to 10cm, which must be controlled at 15°C and the volume of the epoxy mixture must not exceed 15kg per casting. Example: 100cmx10cm x 10cm epoxy lamp. The product has been combined in such a way that anyone can make a simple riverbed, or other artistic work as easily as possible. Epoxy Premium will give you a great result without effort, because: ➡ The product has a low exothermic reaction, for castings up to 7,5 cm thick! ➡ Anti-UV filters provide a 10 year guarantee without yellowing - special light blue tint ensures greater durability over time. ➡ High mechanical resistance surface ensures maximum scratch resistance! ➡ The product is easy to use, ideal for professionals and amateurs alike ➡ Low viscosity for excellent air bubble removal ➡ The product has a long working time to allow intervention and repair of aesthetic defects. -

21.30 € – 33.50 €BE FLEX – scratch resistant and transparent epoxy resin for coating that is easy to use! Be Flex epoxy resin is perfect for creating highly effective protection for many objects such as: Stickers Medals Tags Labels It is also ideal for connecting LED lights and lamps, providing an exceptional protective coating. Applying this special flexible resin is very simple. Thanks to a special formula suitable for coating, it covers the surface and protects it from being flexible and transparent. Simply apply the BeFlex product to the object you want to protect, and after hardening you will have very effective protection: Friction Scratches for moisture. You have a glossy finish, excellent quality and incredible protection.

21.30 € – 33.50 €BE FLEX – scratch resistant and transparent epoxy resin for coating that is easy to use! Be Flex epoxy resin is perfect for creating highly effective protection for many objects such as: Stickers Medals Tags Labels It is also ideal for connecting LED lights and lamps, providing an exceptional protective coating. Applying this special flexible resin is very simple. Thanks to a special formula suitable for coating, it covers the surface and protects it from being flexible and transparent. Simply apply the BeFlex product to the object you want to protect, and after hardening you will have very effective protection: Friction Scratches for moisture. You have a glossy finish, excellent quality and incredible protection. -

48.50 €ICE EPOXY RSE Fast drying epoxy for wood sealing. Penetrates deep into all types of wood fibres. Ideal for sealing epoxy rivers, wood panels and planks used in crack filling. Ice Epoxy RSE epoxy is easy to use because it cures quickly, adheres strongly and can be heated to hardness. Ice Epoxy RSE epoxy resin is UV resistant it has anti-yellowing properties strong adhesion good flowability natural bubble release Low colour and low viscosity allow for bubble-free, crystal clear epoxy repairs, ideal for art and hobby applications. The product is in the gel state for a short time. ICE-RSE has a low VOC content, ensuring user safety and reducing environmental impact.

48.50 €ICE EPOXY RSE Fast drying epoxy for wood sealing. Penetrates deep into all types of wood fibres. Ideal for sealing epoxy rivers, wood panels and planks used in crack filling. Ice Epoxy RSE epoxy is easy to use because it cures quickly, adheres strongly and can be heated to hardness. Ice Epoxy RSE epoxy resin is UV resistant it has anti-yellowing properties strong adhesion good flowability natural bubble release Low colour and low viscosity allow for bubble-free, crystal clear epoxy repairs, ideal for art and hobby applications. The product is in the gel state for a short time. ICE-RSE has a low VOC content, ensuring user safety and reducing environmental impact. -

Sold out

83.50 €Decorative coating that protects all surfaces from moisture and wear (including walls, sloping or vertical surfaces). Advantages: Can be applied with a simple spatula on boards, cement, wood and bricks; The product can repair cracks in the wall or floor, which both repairs and seals the neck at once and makes the surface moisture-resistant again; Creates a new, perfectly shiny and durable layer; The product can be easily sanded to achieve satin finish surfaces; Protects against moisture and gives surfaces a fresh look. This composition of epoxy makes it possible to cover pre-decorated surfaces and walls with a transparent layer or decorate them with a new colored layer, obtaining a glossy, washable and waterproof surface. It can be painted as desired with any color powder, even metallic powders! If you want to get a satin surface, grind it after 48 hours with ordinary sandpaper 1000 (or 2000). USE: Vertical Glass is recommended to be applied with an "American" spatula. – The finish is transparent, but it can also be painted with ResinPro colours if desired – It can be worn in a thin layer for a glazed effect or as a thicker layer for greater consistency and protection – it is possible to achieve artistic effects that design your rooms. Finish after application. USAGE RATIO: Vertical Glass has a standard mixing ratio of 100A:70B. CHOOSE YOUR COLOR! Classic colors: https://loovinterjoor.eu/toode/colorfun-deluxe/ Up to 3.4 kg vertical glass product can be tinted with one jar of 25ml paint. Metallic paints: https://loovinterjoor.eu/toode/sahara-parlpigmendid/ Up to 3.4 kg vertical glass product can be tinted with one jar of 10g of paint.

Sold out

83.50 €Decorative coating that protects all surfaces from moisture and wear (including walls, sloping or vertical surfaces). Advantages: Can be applied with a simple spatula on boards, cement, wood and bricks; The product can repair cracks in the wall or floor, which both repairs and seals the neck at once and makes the surface moisture-resistant again; Creates a new, perfectly shiny and durable layer; The product can be easily sanded to achieve satin finish surfaces; Protects against moisture and gives surfaces a fresh look. This composition of epoxy makes it possible to cover pre-decorated surfaces and walls with a transparent layer or decorate them with a new colored layer, obtaining a glossy, washable and waterproof surface. It can be painted as desired with any color powder, even metallic powders! If you want to get a satin surface, grind it after 48 hours with ordinary sandpaper 1000 (or 2000). USE: Vertical Glass is recommended to be applied with an "American" spatula. – The finish is transparent, but it can also be painted with ResinPro colours if desired – It can be worn in a thin layer for a glazed effect or as a thicker layer for greater consistency and protection – it is possible to achieve artistic effects that design your rooms. Finish after application. USAGE RATIO: Vertical Glass has a standard mixing ratio of 100A:70B. CHOOSE YOUR COLOR! Classic colors: https://loovinterjoor.eu/toode/colorfun-deluxe/ Up to 3.4 kg vertical glass product can be tinted with one jar of 25ml paint. Metallic paints: https://loovinterjoor.eu/toode/sahara-parlpigmendid/ Up to 3.4 kg vertical glass product can be tinted with one jar of 10g of paint. -

16.70 € – 33.50 €Two-component epoxy adhesive that dries in just 5 minutes! The product offers excellent bonding properties in contact with wood, glass, fabric, ceramic tile, stone, plastic, rubber and metal. 🌟 UNIVERSAL ADHESIVE FOR INDOOR AND OUTDOOR APPLICATIONS : ResinPro FixExpress two-component epoxy adhesive is ideal for both indoor and outdoor applications. ⌛ CURE IN 5 MINUTES : This epoxy adhesive can be sanded and also polished after just 20 minutes. 💪 STRONG AND MULTIPLEX : The epoxy molecules ensure excellent adhesion to a wide range of materials such as stone, concrete, plastic, wood, fabric, paper and ceramics. 🎨 CUSTOMIZABLE : FIX EXPRESS can be painted as desired with all Resinpro dyes, bringing your creative ideas to life. 👌 EASY TO USE : Mix 1:1; mix for 30 seconds and apply; job done! 🚫💧 NO DROOPS : FIX EXPRESS is specifically formulated to not create unwanted drips during use. 🔒 SAFE : BPA free; clear and tintable with all Resinpro dyes; two separate bottles avoid unwanted sticking; easy 1:1 mixing ratio. Technical details: Mixing ratio by weight/volume: 1A + 1B. Mix: 30-45 seconds and apply immediately. Working time: 2-3 minutes (at 25°C). Setting time: 5-6 minutes (at 25°C)

16.70 € – 33.50 €Two-component epoxy adhesive that dries in just 5 minutes! The product offers excellent bonding properties in contact with wood, glass, fabric, ceramic tile, stone, plastic, rubber and metal. 🌟 UNIVERSAL ADHESIVE FOR INDOOR AND OUTDOOR APPLICATIONS : ResinPro FixExpress two-component epoxy adhesive is ideal for both indoor and outdoor applications. ⌛ CURE IN 5 MINUTES : This epoxy adhesive can be sanded and also polished after just 20 minutes. 💪 STRONG AND MULTIPLEX : The epoxy molecules ensure excellent adhesion to a wide range of materials such as stone, concrete, plastic, wood, fabric, paper and ceramics. 🎨 CUSTOMIZABLE : FIX EXPRESS can be painted as desired with all Resinpro dyes, bringing your creative ideas to life. 👌 EASY TO USE : Mix 1:1; mix for 30 seconds and apply; job done! 🚫💧 NO DROOPS : FIX EXPRESS is specifically formulated to not create unwanted drips during use. 🔒 SAFE : BPA free; clear and tintable with all Resinpro dyes; two separate bottles avoid unwanted sticking; easy 1:1 mixing ratio. Technical details: Mixing ratio by weight/volume: 1A + 1B. Mix: 30-45 seconds and apply immediately. Working time: 2-3 minutes (at 25°C). Setting time: 5-6 minutes (at 25°C) -

Sold out

Sold out

193.80 €Original price was: 193.80 €.142.50 €Current price is: 142.50 €.POLI SHIELD is the ultimate protective layer that generally protects your floors and surfaces from scratches and wear. The product is applied to the surface with a roller or sprayer on any type of floor. Especially suitable for resin floors (epoxy, acrylic). POLI SHIED is designed to complete the M1-723 cycle to ensure aesthetic, easy-to-wash and durable finishes on surfaces. The product is shiny. ADVANTAGES: Durable and wear-resistant: Special acrylic polyurethane polymers combine the stability and simplicity of acrylic resins and the scratching and wear resistance of the most advanced polyurethane polymers. Easy application: The product is applied with a short-haired roller, foam roller or sprayer. Tools can be cleaned simply with soap and water. The two-component set is ready for use. Versatile and elegant: POLI-SHIELD is available in a variety of finishes: glossy (100 glosses), satin (30 glosses) and matte (with 5 glosses). It is suitable for a wide variety of surfaces: epoxy, acrylic, wood and concrete, and textured finish. At the moment, only a glossy product is available. Easy to maintain: The surface treated with POLI-SHIELD becomes easy to clean with soap, eliminating absorbed dirt and spread bacteria. If necessary, floors under increased load can be re-covered with a roller in worn areas to restore and make the floor shine again as on the first day! Cheap: with one set (2.4 liters) covers up to 25m2 (with a double layer). Are you looking for a cheap, efficient and easy-to-implement solution to protect and upgrade your floors and surfaces in general? POLI-SHIELD is a product for you! -

146.80 € – 264.10 €ICE EPOXY ICECAST crystal clear resin ICECAST is a two component epoxy resin. It is UV-resistant and anti-yellowing. properties. The product has: strong tack, good flowability and natural bubble release. Icecast is designed for medium to large volume applications with thicknesses over 2.5 cm and up to 10-25 cm depending on the volume. Low colour and low viscosity allow crystal clear castings without bubbles. The product is particularly suitable for large volume castings as the product remains in a gel state for a long time after mixing and the low exothermic reaction prevents the product from overheating during the reaction. ICECAST has a low VOC content, which ensures user safety and reduces environmental impact. - 2,5 to 10cm deep casting - Ratio 2A:1B - UV resistant - 100% solid end result - Low VOC content and low odour. - Crystal clear and high gloss appearance - Enhances the appearance of the object - Resistant to bacteria and moisture - Excellent air separation properties - Does not age

146.80 € – 264.10 €ICE EPOXY ICECAST crystal clear resin ICECAST is a two component epoxy resin. It is UV-resistant and anti-yellowing. properties. The product has: strong tack, good flowability and natural bubble release. Icecast is designed for medium to large volume applications with thicknesses over 2.5 cm and up to 10-25 cm depending on the volume. Low colour and low viscosity allow crystal clear castings without bubbles. The product is particularly suitable for large volume castings as the product remains in a gel state for a long time after mixing and the low exothermic reaction prevents the product from overheating during the reaction. ICECAST has a low VOC content, which ensures user safety and reduces environmental impact. - 2,5 to 10cm deep casting - Ratio 2A:1B - UV resistant - 100% solid end result - Low VOC content and low odour. - Crystal clear and high gloss appearance - Enhances the appearance of the object - Resistant to bacteria and moisture - Excellent air separation properties - Does not age -

48.50 € – 116.50 €ICE EPOXY THIN is a two-component epoxy resin kit. The product is UV resistant, has anti-yellowing properties, strong bonding properties, good flowability, fast curing. It can be used for surface coating or light casting in thicknesses from 1,6 mm to 2,5 cm. Its low colour and high viscosity allow epoxy to set quickly and create crystal-clear works, ideal for artistic and hobby applications. This epoxy resin is prepared in such a way that the product remains in the gel state for a short time. ICETHIN has a low volatile organic compound (VOC) content which ensures user safety and reduces environmental impact. - Casting less than 2,5cm - Ratio 1A:1B - UV resistant - High viscosity - Fast curing - Low volatile organic compounds and low odour - Crystal clear and high gloss appearance - Enhances the appearance of the object - Resistant to bacteria and moisture - Excellent air separation properties - Does not age

48.50 € – 116.50 €ICE EPOXY THIN is a two-component epoxy resin kit. The product is UV resistant, has anti-yellowing properties, strong bonding properties, good flowability, fast curing. It can be used for surface coating or light casting in thicknesses from 1,6 mm to 2,5 cm. Its low colour and high viscosity allow epoxy to set quickly and create crystal-clear works, ideal for artistic and hobby applications. This epoxy resin is prepared in such a way that the product remains in the gel state for a short time. ICETHIN has a low volatile organic compound (VOC) content which ensures user safety and reduces environmental impact. - Casting less than 2,5cm - Ratio 1A:1B - UV resistant - High viscosity - Fast curing - Low volatile organic compounds and low odour - Crystal clear and high gloss appearance - Enhances the appearance of the object - Resistant to bacteria and moisture - Excellent air separation properties - Does not age

Which ResinPro epoxy resin to choose?

Resinpro products are designed with ordinary users in mind. For this purpose, a very wide range of different ResinPro epoxy resins has also been created to ensure that customers have freedom of choice and find the right epoxy resin for their work or to do.

In our online store, the product range of epoxy resins is divided into 8 main groups

- A layer up to 1cm thick for painting and coating(this should then be a link to the groups of the given product)

In this group of products, epoxy resins are suitable for covering floors, kitchen countertops, tables and other artworks to protect surfaces, give gloss and depth. You will also find epoxy resins specially designed for painting, which are thicker in consistency and do not allow paints to mix with each other. - Universal castings up to 2 cm thick(it should then be a link to the groups of a given product)

In this group of products you will find the most universal products with which you can experiment with almost all the activities that belong to the hobby of epoxy resin. If the creation is already in your paw, you can also want a more specific product. The best products to start and test. - Casting up to 5 cm thick(it should then be a link to the groups of a given product)

In this group of products there are epoxy resins, which are intended mainly for making river boards (rivertable). But the products are suitable for pouring any thicker layer, since the drying period of the product is brought longer, and this ensures calm and low-temperature drying. - Up to 10cm thick casting(it should then be a link to the groups of a given product)

Here you can find a suitable product for making especially massive and large dining tables. Also, the product is suitable for drowning various items. Very good product for large projects. - Polyurethane resins(this should then be a link to the groups of a given product)

Here you can find resins with a different chemical compound, which are also designed to make and cover 3D models. - BIO, ECO and Food resistant epoxy resins (this should then be a link to the given product groups)

These products are designed with those customers who attach importance to safety and responsible production. - UV hardening resins and extras(this should then be a link to the groups of the given product)

UV petrifying products are unicellular resins that react to UV light. The product hardens when UV light shines on the product. These products dry very quickly and are easy to use - Glass fiber and Carbon(Carbon fiber) products(this should then be a link to the given product groups)

Epoxy resin specially designed for coating and fixing glass fabrics and carbon fibers.

Epoxy resin – what substance is it and where can we find it?

- Epoxy is a common colloquial name that refers to any component or cured end product of epoxy resin.

- Epoxy resin is a two-component liquid polymer that is thermo-curing.

- Simply put, epoxy resin is a liquid consisting of hardener and resin, which solidifies when the hardener and resin mix, thanks to the reaction of catalysis.

Epoxy resins have been in use for more than 50 years and are among the most successful plastic families. Their physical state can be transformed from a low viscosity liquid into a solid with a high melting point, which means that a wide range of materials with unique properties can be made.

At home, you can find them in cans of soft drinks and in special packages, where they are used as lining to protect the contents and keep the taste. They are also used as a protective coating everywhere. Such as:

- Beds

- Gardens

- Chairs

- office and hospital furniture,

- supermarket carts,

- jalgratad

- etc.

They are also used in special paints to protect the surfaces of ships, oil drilling rigs and wind turbines from bad weather.

Properties of epoxy resin.

The physical state of epoxy resins can vary from a low viscosity liquid to a solid with a high melting point. They can be cross-linked using a variety of hardeners, forming materials with a unique combination of properties that bring advantages in key industrial sectors.

Epoxides are known for their excellent

- adhesion,

- chemical and heat resistance,

- outstanding mechanical properties,

- very good electrical insulating properties.

Many of their properties can be changed, for example, silver-filled epoxides with good electrical conductivity are available, while epoxys are usually electrically insulating. Variations are available that provide high thermal insulation or thermal conductivity in combination with high electrical resistance for electronic devices.

Description of the process of drying epoxy resin

Epoxy resins are thermosetting polymers with unique mechanical and durable properties. They arise from a chemical reaction called "hardening," which involves epoxides and other chemicals more commonly known as hardeners.

A number of substances can be used as hardeners, including:

- polyamines,

- aminoamides, or

- phenolic compounds.

The hardening process consists of an exothermic reaction, which is achieved either by the reaction of epoxy resins with themselves (catalytic homopolymerization) or by crosslinking with a hardener. As a result of the hardening process, thermosetting polymers of epoxy are created, which have a unique effect:

- adhesion,

- Durability

- Versatility.

Depending on the desired result, different types of epoxy resins can be mixed. It is also possible to mix additives, plasticizers or fillers to modulate the final characteristics of specific uses.

Epoxy resin and areas of their application

The areas of application of epoxy resins are extensive, and their application can be found in the following places:

- Paints and coatings.

- Adhesives.

- Composite materials, such as carbon fiber and fiberglass reinforcements.

- Industrial tools and composites.

- Electrical systems and electronics.

- Consumer applications.

- Marine applications.

- Aerospace applications.

- Biology.

- Art.

- Furniture industry.

- Hobby