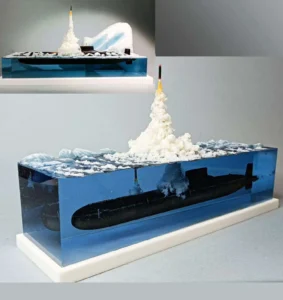

Innovation and resilience for your bold projects

LUXRESIN is the leading two-component polyurethane resin in its field. Ideal for projects where exceptional strength and durability are required. Its advanced formula ensures crystalline transparency with excellent resistance to collapse even in thicker thicknesses. The ingredients of this product ensure a high level of resistance to indoor and outdoor environments, effectively withstanding even intense UV radiation.

Exceptional options

LUXRESINi eripäraks on tänu madalale eksotermilisele reaktsioonile (<50°C) võime valada kuni 40 cm paksuse kihina. See täiustatud tehnoloogiline aspekt võimaldab luua suure sügavusega töid, säilitades samas täiusliku kontrolli reaktsioonisoojuse üle, mis on oluline eelis uuenduslike ja julgete projektide jaoks.

To obtain a perfectly homogeneous surface, it is recommended NOT to apply the product in layers of less than 5 mm.

Excellent mechanical properties

After curing, LUXRESIN provides excellent mechanical properties combined with surface hardness and abrasion resistance that set new standards in the industry. Its versatility makes it ideal for projects requiring a high level of aesthetics and durability over time.

Thanks to its high performance, this product is ideal for dry surfaces, as residual moisture can create air bubbles during catalysis.

Transparency and anti-corrosion protection

Luxresin offers unparalleled transparency and complete, long-lasting protection against yellowing. These features ensure that the beauty and transparency of your creations remain intact over time: Luxresin is the perfect companion for your most precious applications!

Technical advice for optimal implementation:

Removing air: use a vacuum pump to remove air bubbles from the mixture. This step is essential to ensure a highly transparent end result.

Air removal procedure: mix the resin thoroughly, insert it into the vacuum pump and apply the vacuum in three stages. Apply the resin and gradually reduce the size and volume of the bubbles in each stage.

Lack of moisture: make sure that the surface you are applying the resin to is completely dry before applying. Before you apply the resin, make sure that the entire surface of the resin is completely dry before you apply the resin. Any moisture may react with the isocyanate, causing bubbles every few hours.

Polishing: Polish within a maximum of two weeks after application. After this time, the resin becomes too hard, making the polishing process much more difficult.

Additional considerations:

Caution: Luxresin requires more care than epoxy resins due to its sensitivity to moisture (water molecules react with the resin to create air bubbles), but provides a more durable result than traditional resins.

Fee in three equal payments 3 x

Fee in three equal payments 3 x